| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : ECOOGRAPHIX

Model Number : ECOO-T1400FA

Certification : CE

Place of Origin : CHINA

MOQ : 1set

Price : Negotiable

Payment Terms : L/C, T/T

Supply Ability : 500SETS

Delivery Time : about 20days

Packaging Details : Standard Export Packing

Max Machine Speed : 300m/min

Max.Unwinding Width : 1600mm

Application : plastic film (PVC,OPP,PET, CPP), paper, glass paper, aluminum-foil paper, aluminum foil, adhesive sticker

Max. load capacity : 3ton

Weight : 4000KGS

Overall Dimension : 3100*2100*1900mm

Condition : New

Sea port : Shanghai

Max Rewinding : 300mm

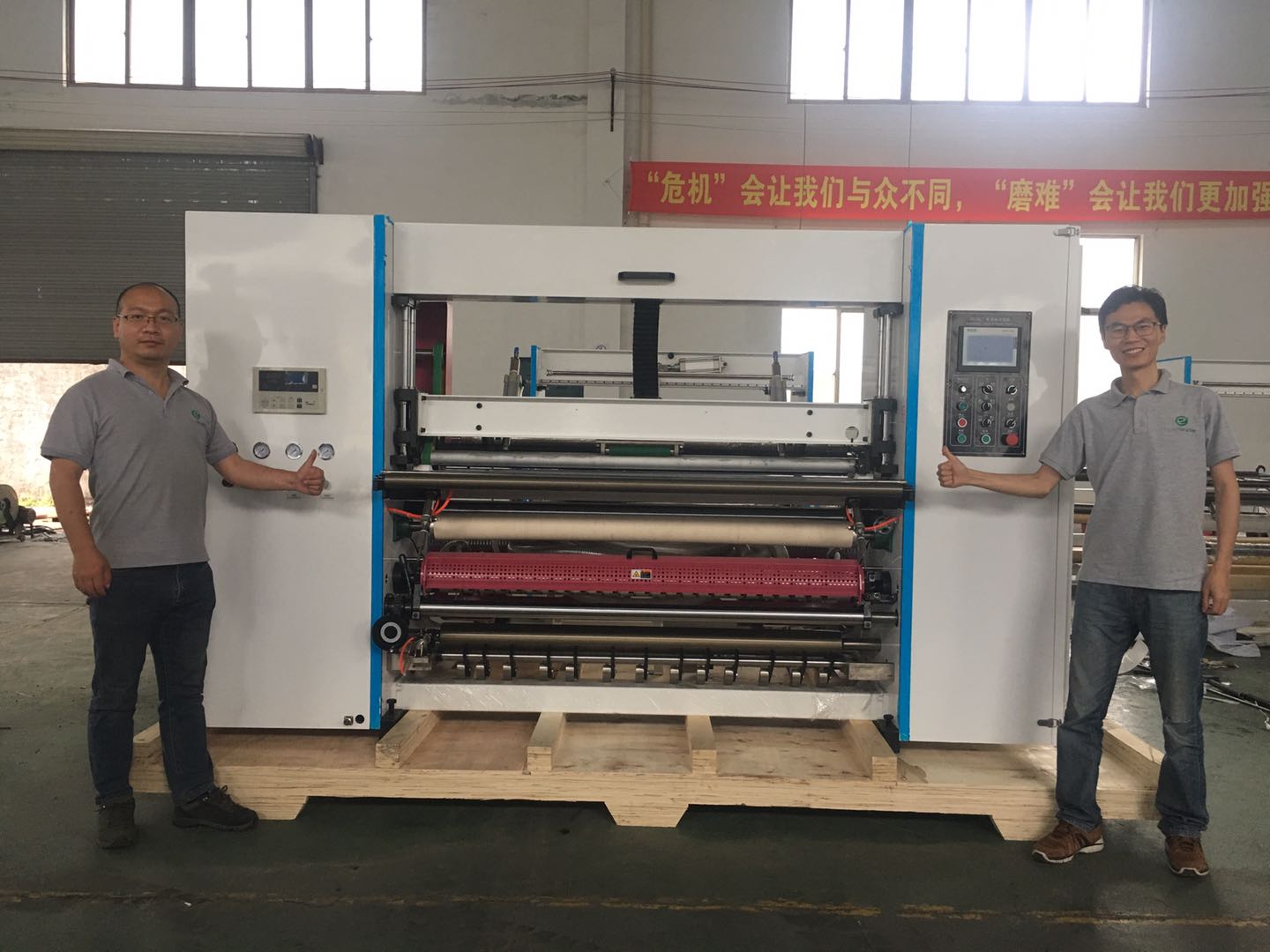

Online ATM POS Thermal Paper Slitting and Rewinding Line Machine

ECOO-T1400FA

EcooGraphix T-1400FA is ideal for slitting various ultra-large coiled materials including plastic films (PVC, OPP, PET, CPP), paper, glass paper, aluminum-foil paper, aluminum foil, adhesive stickers, non-woven fabrics, and other materials, ensuring precise slitting and rewinding.

2. Main Parameters:

| Model | Ecoo-1400FA |

| Max. Parent Web Width | 1400mm |

| Max. Parent Web Diameter | 1200mm |

| Max. Rewinding Diameter | 300mm |

| Min. Slit Width | 15mm |

| Max. Machine Speed | 300m/min |

| Torque | 100Nm |

| Unwinding Type | 3” air expanding shaft |

| Rewinding Shaft | 0.5”, 1” are available (or as your request) |

| Power | 20KW |

| Voltage | 3 phase, 380V, 50Hz |

| Weight | 4000kg |

| Dimension | 5500*2200*1880mm |

Ecoo-1400FA enables seamless thermal paper production from core feeding to roll packing, streamlining the process into a single operation.

With Ecoo-1400FA, you can effortlessly produce 23,000 to 35,000 pieces of 57mm x 50mm till rolls within 8 hours, without the need for a dedicated operator.

To provide a comprehensive understanding of the newly released Ecoo-1400FA automatic thermal paper production line, we'll break down its operation step by step. You can view the demo video on YouTube for reference.

Core feeding is automated using an automatic core feeder. Simply place the plastic core in the bowl beforehand, and the core feeder will autonomously push it onto the core staging conveyor.

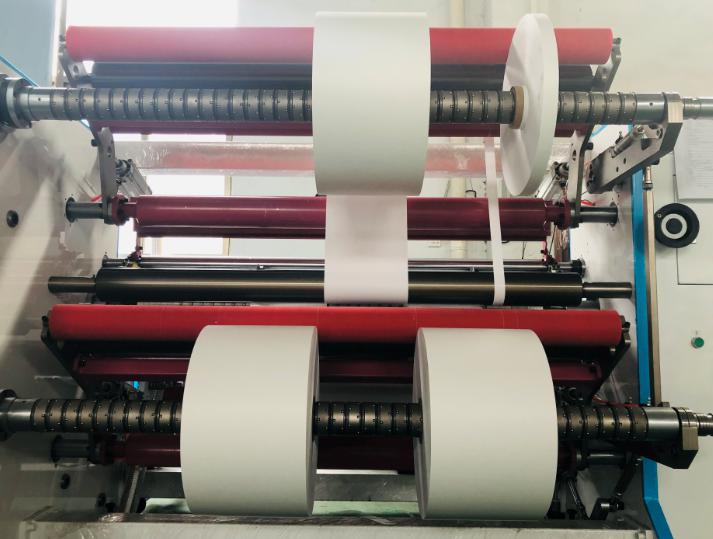

| Unwinding section | - 3”(76mm)air expanding rewinding shaft |

| Slitting Section | - Choices of Razor cutter or Disc cutter |

| Rewinding Section | - 3”air expanding rewinding shafts |

| Controlling Section | - Inovance PLC & HMI |

| Trimmed Waste Edge | -Edge Waste Blower with Expulsion Tube |

| Optional | - 6'' and 12” Unwinding shafts |

|

|

ECOO-T1400FA Shaftless Hydraulic Loading Thermal Paper Slitting Rewinding Machine Images |